HISTORY OF FORSYTHE

History Timeline

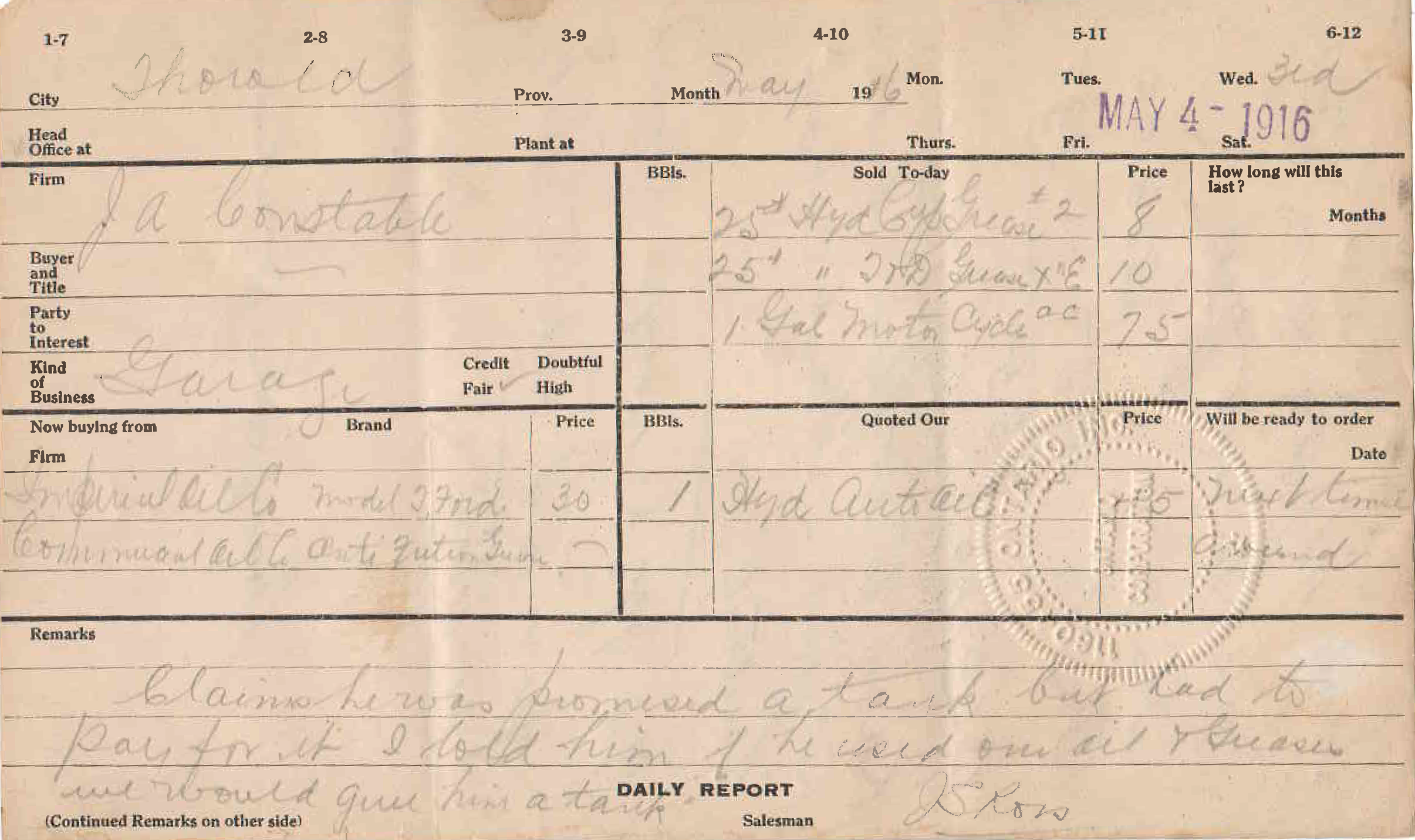

1911-1933

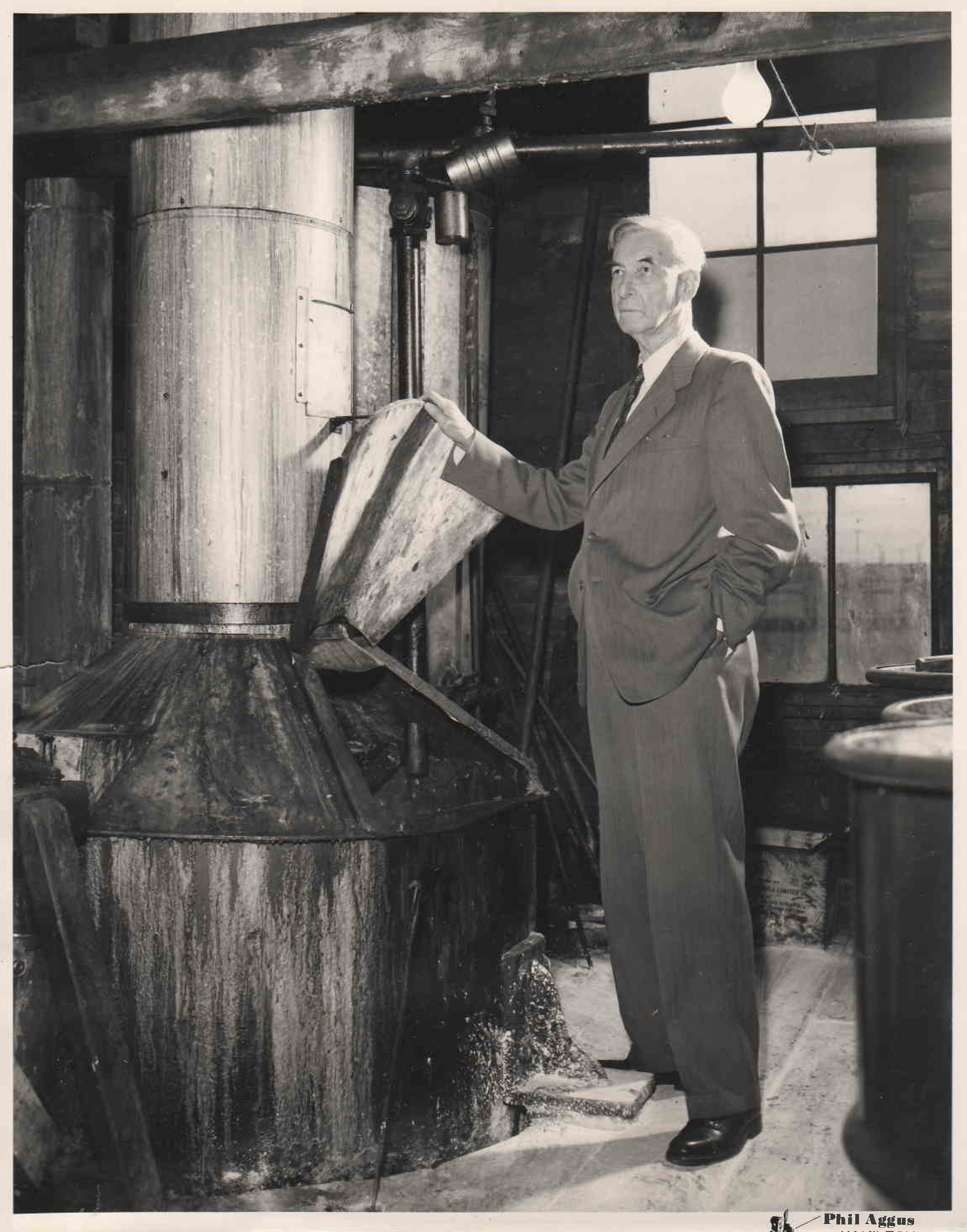

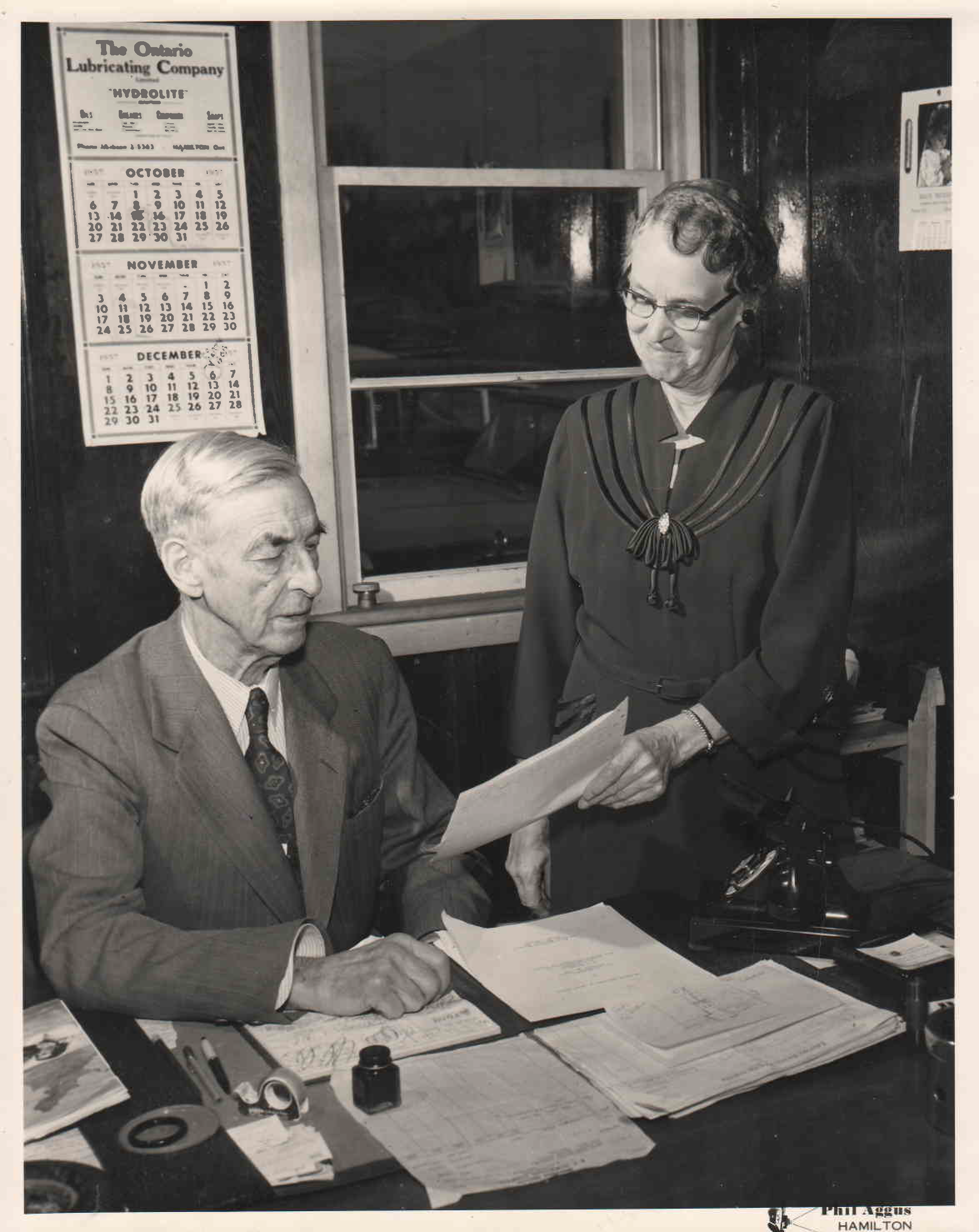

In 1911, Chester Goring saw an opportunity. The Steel Company of Canada had just been established in Hamilton, Ontario and would need a supplier of industrial lubricants. Chester’s background working at an industrial oil company in Buffalo, New York provided him the experience he needed to establish his own lubricant manufacturing business, “The Ontario Lubrication Company Limited”. The site he chose was 120 Chatham Street, Hamilton, Ontario, a piece of land approximately 4 acres in size, with the Canadian Pacific Rail siding, and proximity approximately 10 kilometers from The Steel Company. There was a small house on the property that he used as an office, as well as a large out building where a basic line of industrial lubricants including hydraulic and gear oils, as well as various greases were made. Primitive testing methods at that time were to view a sample of the lubricant up to a light looking for particulates and colour, as well as a visual and pour test performed for viscosity. Chester hired two men for manufacturing, and a secretary. Business grew due to increasing industrial business in the Hamilton area for several decades.

- Ontario Lubrication Established

- Purchase of 120 Chatham Street Hamilton, Ontario

- Focus on industrial lubricants being sold to steel mills, processors, and local heavy industry

- Expanded business during WWI supplying industrial and metalworking lubricants into Canadian and US Military

1936-1954

- Gordon Goring joins Ontario Lubrication (Chester’s son) 1946

- Supplied Canadian and US Military during WWII with metalworking and industrial lubricants

- Expanded brand name to mining, forestry, and die cast lubricants

- Added blending vessels and on site lubricants laboratory

- Survived through periods of economic boom and decline

1955-1962

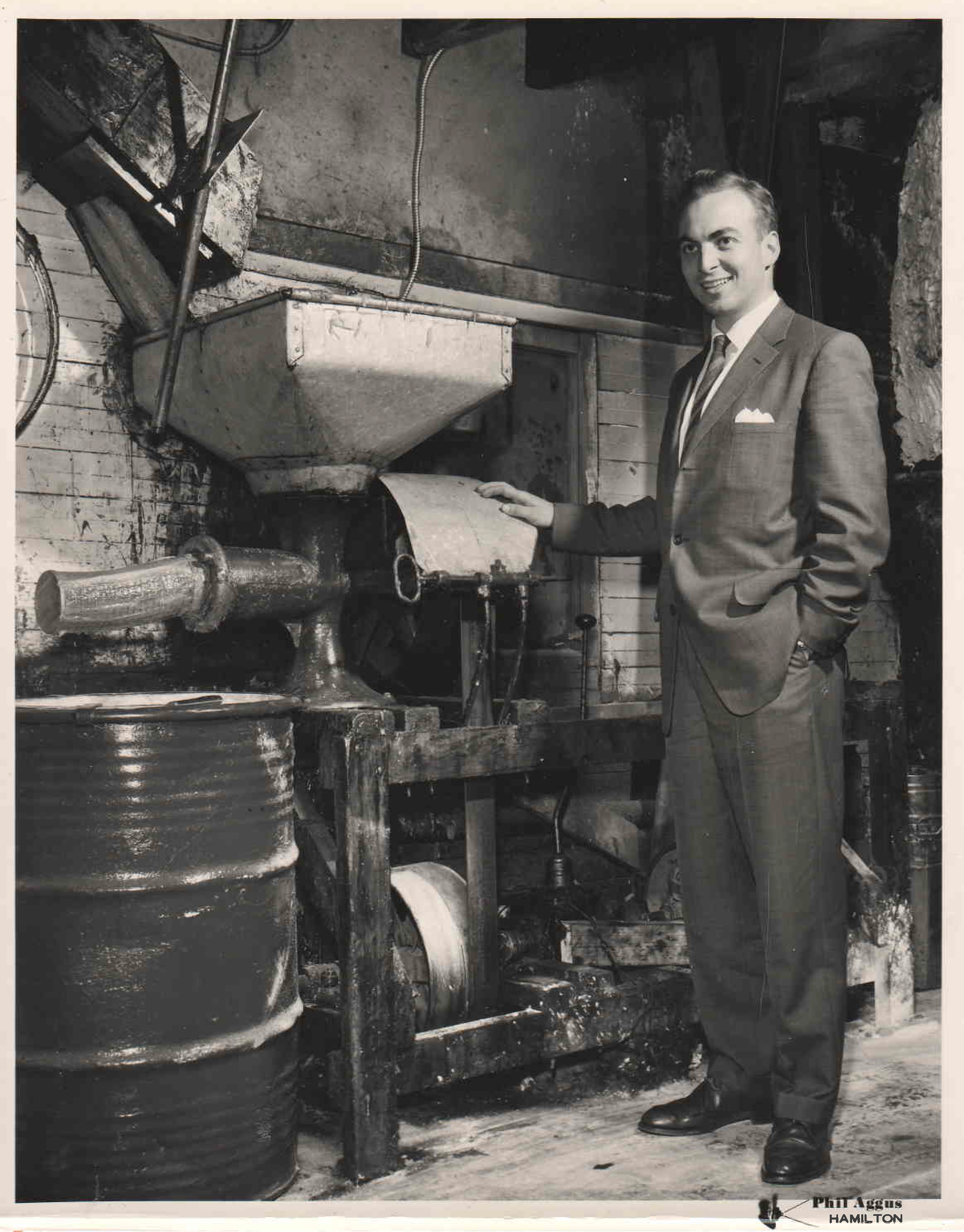

Bob Forsythe, Chester’s grandson, joins Ontario Lubrication in 1955. There was a need for more lubricant technology and development to serve increasingly complex systems. Bob developed “Hydrolite”, a trademarked lubricant to be used at the Niagara Power Generation Station. He also formulated products for the mining, forestry, and die cast industries, that increased business across Ontario. Due to the significant increase in business, more blending vessles and warehousing were added. Profits doubled due to Bob’s efforts between 1955-1962.

- Continued growth into steel, forestry, die cast, and manufacturing

- Sales expanding out of Southern Ontario

- Formulated “Hydrolite” for use in power generation plants across in Ontario

- Joined STLE and launched Hamilton Chapter

- Building expansion with warehouse and added manufacturing capacity

- Grease manufacturing expansion

1963-1969

In 1963 Chester Goring retired, leaving Ontario Lubrication to his son Gordon Goring who had been working in the business for several years, however not adding anything to the bottom line. Gordon’s first decision was to fire his nephew Bob Forsythe.

Bob felt confident his relationships with the customers he secured would hold strong, and established his own lubrication manufacturing business, “Forsythe Lubrication”. Bob’s mother Gladys (nee Goring) loaned Bob the money to purchase a plant in Dundas, Ontario to compete with her brother’s Ontario Lubrication company.

Forsythe’s sales continued to grow. Within five years, Gordon put The Ontario Lubrication Company into bankruptcy, and the facility at 120 Chatham Street was put up for sale. Bob purchased the property and renovated the original building for increased office space.

- Forsythe Lubrication Established with new brand names and management

1970-1974

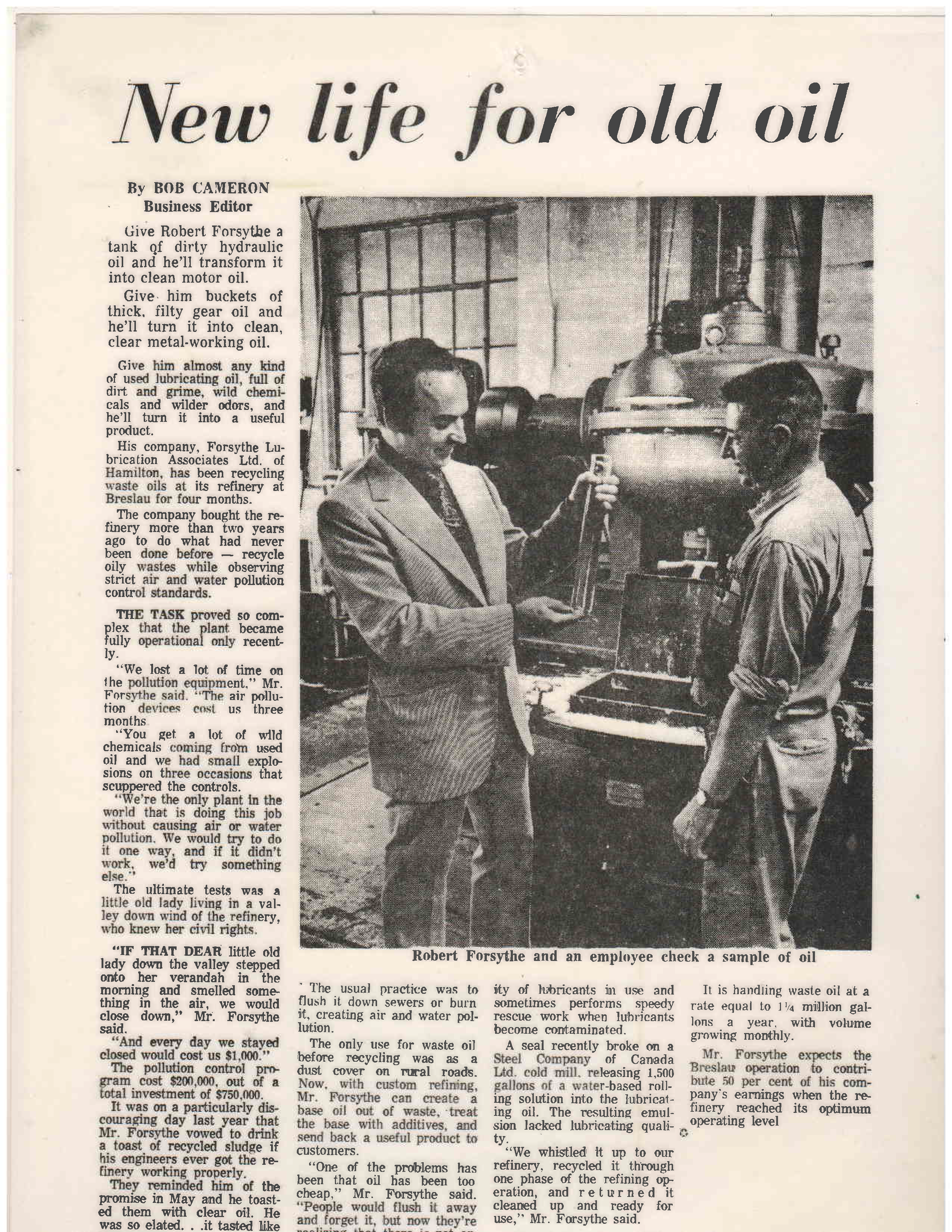

- Purchase of Breslube re-refining facility and efforts toward environmental stewardship

- Canadian Government policy increased price of waste oil resulting in lack of viable business model

- Breslube sold in 1976 – better known today as Safety Kleen Breslau Ontario

1975-1979

Gulf Oil, at that time, were undergoing a major renovation at their Lubeplex facility in Mississauga. They needed a lubricant manufacturer to produce their formulated products for the period of a year while they were shut down for renovations. Due to Forsythe’s proximity and track record of excellent service, they were chosen to Contract Blend on Gulf Oil’s behalf. The increased volume of business and necessary expansion for tanks was needed, with the plant running 24/7. Contract Blending became the norm for major oil companies who did not have kettle blending for niche products, and Forsythe grew to Contract Blend for most majors including Shell, Imperial, and Pennzoil

- Contract Blending for major oil companies begins

- Rapid expansion of manufacturing, warehousing, and packaging capabilities and capacities

1980-1994

- Exploration of new markets and territories

- Distribution throughout North America for phosphate ester fluids into power generation

- Joint venture with US company for expansion of metalworking fluids

1995-2000

Blending for major oil companies required ISO certification that was achieved in 1997, by long standing employee Albert Boyle and Dee Forsythe who joined the business in 1979. The internet was a new method of marketing and provided the mechanism for new global sales. Forsythe’s first distributor was set up in Thailand. Global business and reputation grew across Asia and Europe and South America.

- ISO 9001 certification achieved

- Forsythe website created

- Marketing efforts concentrate on large users worldwide and distribution (Asia, Europe, South America)

2001-2010

An opportunity to Contract Blend Automatic Transmission Fluid for a Japanese oil company presented itself, with Albert and Dee joining forces again to obtain the business. One year later after plant modification for dedicated systems and monthly audits from Japan and the US, Forsythe were supplying automotive factory fill fluids.

Our reputation spread to Germany who requested Forsythe be their Contract Blender for Shock Absorber Fluids to be manufactured for factory fill across the United States and Mexico.

- Contract blending expands to Germany and Japanese companies

- Dedicated systems are introduced

- Automotive factory fill throughout North America

- ISO IATF 16949 achieved

2011

- 100 years of success with 5th generation now involved

- Manufacturing and laboratory expansion

- Continued growth in contract blend/packaging and Forsythe branded products