How We Started

Back in 1910, Chester Goring was working in Buffalo New York at a lubrication company, and had been for many years. In Hamilton, Ontario, The Steel Company of Canada (Stelco) was established in 1911 and Chester saw an opportunity to use his experience and start his own lubricant manufacturing business on 120 Chatham Street in Hamilton. The location was a good one due to the railroad next to the property and close proximity to the manufacturing section of Hamilton. Chester moved his wife Edith Goring and their young daughter Gladys Goring from Buffalo NY to Markland Street in Hamilton to establish “Ontario Lubricating Company”.

Ontario Lubricating Company manufactured a standard line of industrial lubricants and also formulated specialty lubrication for specific applications. Formulas were hand written on a piece of paper, some of which we still have in historical files. At that time, quality control was to hold the lubricant up to the light in a beaker to look for clarity. The first customer was Stelco, now U.S. Steel who we continue to supply today.

How We Started

Back in 1910, Chester Goring was working in Buffalo New York at a lubrication company, and had been for many years. In Hamilton, Ontario, The Steel Company of Canada (Stelco) was established in 1911 and Chester saw an opportunity to use his experience and start his own lubricant manufacturing business on 120 Chatham Street in Hamilton. The location was a good one due to the railroad next to the property and close proximity to the manufacturing section of Hamilton. Chester moved his wife Edith Goring and their young daughter Gladys Goring from Buffalo NY to Markland Street in Hamilton to establish “Ontario Lubricating Company”.

Ontario Lubricating Company manufactured a standard line of industrial lubricants and also formulated specialty lubrication for specific applications. Formulas were hand written on a piece of paper, some of which we still have in historical files. At that time, quality control was to hold the lubricant up to the light in a beaker to look for clarity. The first customer was Stelco, now U.S. Steel who we continue to supply today.

The company was prosperous and provided the Gorings an affluent lifestyle. Chester and Edith had a second child named Gordon, and both children were sent to private schools. Gordon was not an academic and preferred a fast and flirtatious lifestyle, including dating Evelyn Dick, who turned out to be involved in one of Hamilton’s most notorious murder trials. Chester determined it would be best that Gordon join his business to enable him to earn a living, although he was not the least bit interested in the business, and was basically along for the ride.

By this time, Gladys had finished school at Bishop Straughn in Toronto, and fallen in love with Robert E. Forsythe from Hagersville, Ontario. Bob was a farm boy from a family of 6 and not considered marriage material due to their lack of income, education and class. Gladys was headstrong and determined for a woman of that time and chose to marry him in 1932 without her parents’ blessing. Chester and Edith made it clear to Gladys that she would no longer be supported in any way including financially from them. Bob and Gladys moved to a small home on Locke Street, and Bob found work at Stelco as a labourer. In 1933, they had a son they named Robert Goring Forsythe (Jr). Bob and Gladys could not afford a hospital birth of their son “Bobby” and he was born at home after a most difficult three day breach birth.

The company was prosperous and provided the Gorings an affluent lifestyle. Chester and Edith had a second child named Gordon, and both children were sent to private schools. Gordon was not an academic and preferred a fast and flirtatious lifestyle, including dating Evelyn Dick, who turned out to be involved in one of Hamilton’s most notorious murder trials. Chester determined it would be best that Gordon join his business to enable him to earn a living, although he was not the least bit interested in the business, and was basically along for the ride.

By this time, Gladys had finished school at Bishop Straughn in Toronto, and fallen in love with Robert E. Forsythe from Hagersville, Ontario. Bob was a farm boy from a family of 6 and not considered marriage material due to their lack of income, education and class. Gladys was headstrong and determined for a woman of that time and chose to marry him in 1932 without her parents’ blessing. Chester and Edith made it clear to Gladys that she would no longer be supported in any way including financially from them. Bob and Gladys moved to a small home on Locke Street, and Bob found work at Stelco as a labourer. In 1933, they had a son they named Robert Goring Forsythe (Jr). Bob and Gladys could not afford a hospital birth of their son “Bobby” and he was born at home after a most difficult three day breach birth.

Christmas rolled around and Gladys was at a loss to provide gifts for Bob’s large family and chose to use the sewing skills she acquired in school to make fancy handbags out of felt, that were a huge hit. Gladys was growing weary of the sparse living the small wage Bob earned at Stelco, and had not been able to afford the basics for Bobby and began sewing bags for friends and selling them. She established a business out of her home called “Glad Bag Creations” making one of a kind hats and bags for the affluent women in town. Her business grew quickly and she was frowned upon by neighbours for being a working wife, which was unheard of at that time.

Ontario Lubricating continued to grow and provide the Gorings the lifestyle they were accustomed to. When Bobby reached his mid-teens, he worked summers there cleaning out wooden oil barrels. Around that time Stelco had a Union, and there was a strike. It would be challenging to get lubricants in to continue production. Bobby was chosen to load a small boat at the mouth of the Hamilton Harbour and make his way over to Stelco with drums of oil to continue supply.

Christmas rolled around and Gladys was at a loss to provide gifts for Bob’s large family and chose to use the sewing skills she acquired in school to make fancy handbags out of felt, that were a huge hit. Gladys was growing weary of the sparse living the small wage Bob earned at Stelco, and had not been able to afford the basics for Bobby and began sewing bags for friends and selling them. She established a business out of her home called “Glad Bag Creations” making one of a kind hats and bags for the affluent women in town. Her business grew quickly and she was frowned upon by neighbours for being a working wife, which was unheard of at that time.

Ontario Lubricating continued to grow and provide the Gorings the lifestyle they were accustomed to. When Bobby reached his mid-teens, he worked summers there cleaning out wooden oil barrels. Around that time Stelco had a Union, and there was a strike. It would be challenging to get lubricants in to continue production. Bobby was chosen to load a small boat at the mouth of the Hamilton Harbour and make his way over to Stelco with drums of oil to continue supply.

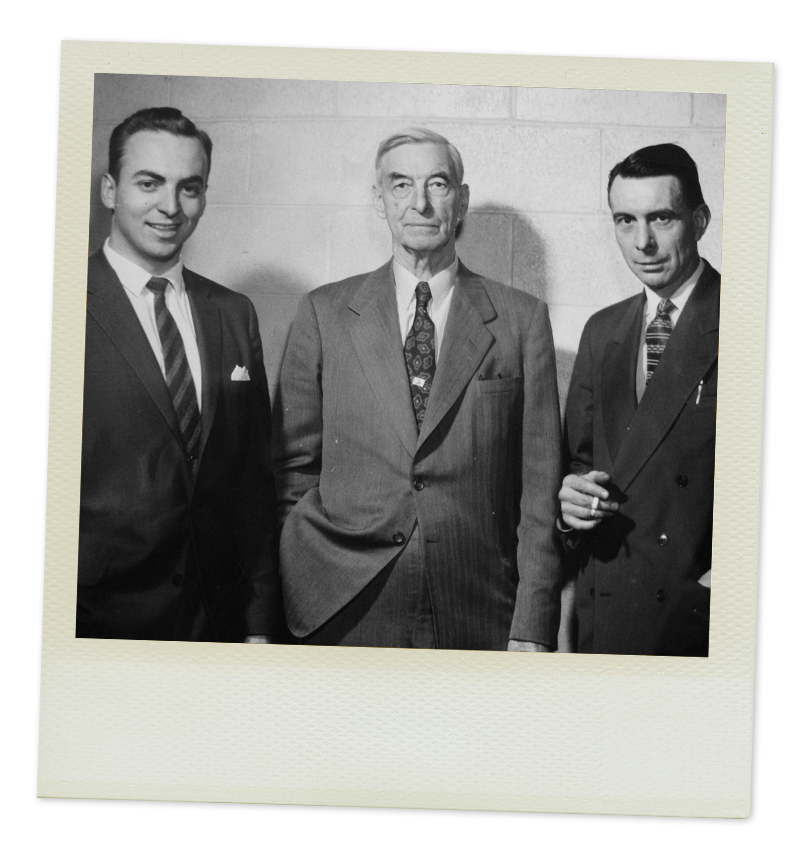

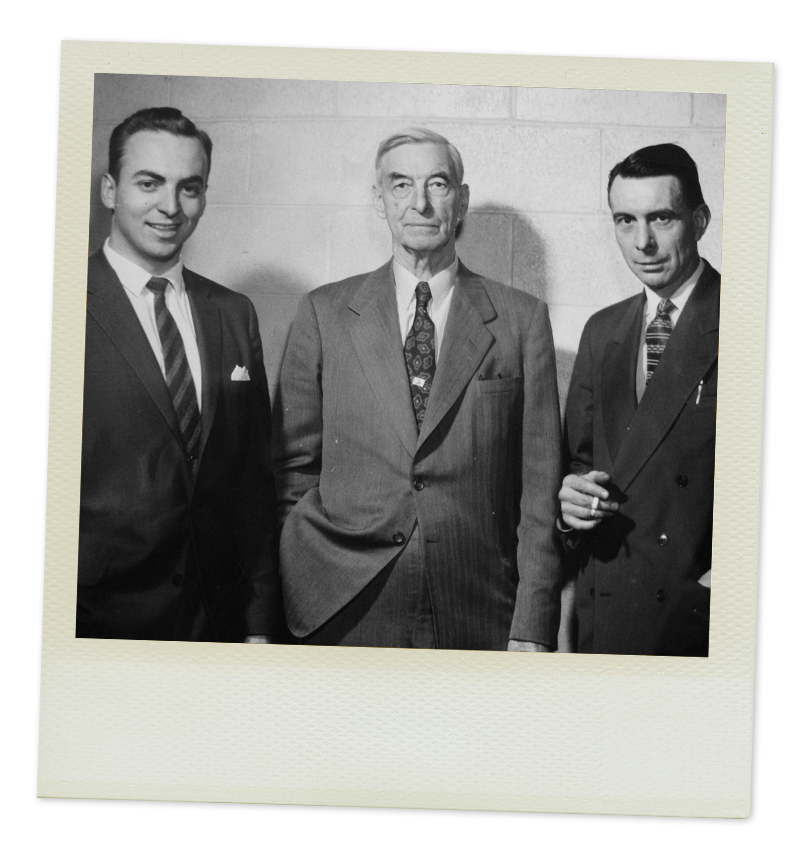

He earned enough money to attend Georgia Tech School, and a couple of years at McMaster University, but was anxious to start earning a living. His sales skills were honed helping his mother Gladys in her business that had grown to supplying boutiques in Long Island, NY, and out to Banff Springs Hotel. Chester saw potential in his grandson and offered Bobby a job in sales at Ontario Lubricating in the early 50’s. Sales grew into northern Ontario at the mines (INCO) and throughout Southern Ontario to necessitate a significant expansion at Ontario Lubricating for new blending vessels and holding tanks. Bobby formulated specialty lubricants including “Hydrolite” for the power generation station in Niagara Falls. In historical files we have the profit graph from Ontario Lubricating from 1911 to 1963 as evidence of growth.

By this time, Chester wanted to retire and the difficult decision arose of who should take over the business. His son Gordon, who had ridden on the family’s coattails or his grandson Bobby, who had proven himself a seasoned and successful salesman. Chester opted to put Ontario Lubricating into the hands of his son Gordon.

On December 23rd 1961, Bob was working late at the office, and a sheriff came to the door with a letter from his Uncle Gordon advising he was no longer employed (in historical files), and asked that his car keys be handed over. Bob used his sales skills and managed to have the sheriff provide him a ride home to Hyde Park Avenue. The next morning Bobby visited his grandfather and advised he would be going into business for himself as a competitor to Ontario Lubricating. Chester said he was entitled to any business he could win, but doubted without financial backing and no manufacturing facility that he would be successful. Bob’s last words to his grandfather were “watch me” and walked out.

Gladys had earned significant money over the years with “Glad Bag Creations” and loaned all she had made to Bob to set up shop in her garage on Hess Street to compete with her brother Gordon. Within a 10 day period, Bobby established “Forsythe Lubrication” and was able to purchase the necessary raw materials and blended lubricants himself to meet his customer’s needs. Relationships had been established with them over the years, and they knew the service Bob provided. Not long after, space was rented on Sherman Avenue to blend lubricants and Forsythe Lubrication continued to grow. The following year, Bob purchased a property on Hatt Street in Dundas.

By this time, Gladys felt it was time to close her business “Glad Bag Creations” and shut her doors. Proctor and Gamble liked the name of her business and wanted to use it for their line of garbage bags, offering a sum of $100.00 to use it. Gladys was incensed at the prospect of her name being used on garbage bags and declined selling it. Proctor and Gamble used a sly method of stealing her name and put a dot between Glad and Bag that Gladys’ lawyers advised against fighting such a legal battle with a large corporation.

He earned enough money to attend Georgia Tech School, and a couple of years at McMaster University, but was anxious to start earning a living. His sales skills were honed helping his mother Gladys in her business that had grown to supplying boutiques in Long Island, NY, and out to Banff Springs Hotel. Chester saw potential in his grandson and offered Bobby a job in sales at Ontario Lubricating in the early 50’s. Sales grew into northern Ontario at the mines (INCO) and throughout Southern Ontario to necessitate a significant expansion at Ontario Lubricating for new blending vessels and holding tanks. Bobby formulated specialty lubricants including “Hydrolite” for the power generation station in Niagara Falls. In historical files we have the profit graph from Ontario Lubricating from 1911 to 1963 as evidence of growth.

By this time, Chester wanted to retire and the difficult decision arose of who should take over the business. His son Gordon, who had ridden on the family’s coattails or his grandson Bobby, who had proven himself a seasoned and successful salesman. Chester opted to put Ontario Lubricating into the hands of his son Gordon.

On December 23rd 1961, Bob was working late at the office, and a sheriff came to the door with a letter from his Uncle Gordon advising he was no longer employed (in historical files), and asked that his car keys be handed over. Bob used his sales skills and managed to have the sheriff provide him a ride home to Hyde Park Avenue. The next morning Bobby visited his grandfather and advised he would be going into business for himself as a competitor to Ontario Lubricating. Chester said he was entitled to any business he could win, but doubted without financial backing and no manufacturing facility that he would be successful. Bob’s last words to his grandfather were “watch me” and walked out.

Gladys had earned significant money over the years with “Glad Bag Creations” and loaned all she had made to Bob to set up shop in her garage on Hess Street to compete with her brother Gordon. Within a 10 day period, Bobby established “Forsythe Lubrication” and was able to purchase the necessary raw materials and blended lubricants himself to meet his customer’s needs. Relationships had been established with them over the years, and they knew the service Bob provided. Not long after, space was rented on Sherman Avenue to blend lubricants and Forsythe Lubrication continued to grow. The following year, Bob purchased a property on Hatt Street in Dundas.

By this time, Gladys felt it was time to close her business “Glad Bag Creations” and shut her doors. Proctor and Gamble liked the name of her business and wanted to use it for their line of garbage bags, offering a sum of $100.00 to use it. Gladys was incensed at the prospect of her name being used on garbage bags and declined selling it. Proctor and Gamble used a sly method of stealing her name and put a dot between Glad and Bag that Gladys’ lawyers advised against fighting such a legal battle with a large corporation.

In 1966 Bobby was made aware that Ontario Lubricating had gone into bankruptcy and the property at 120 Chatham Street was up for sale. Discussion with Gordon ensued who refused to sell it to Bob given their bitter history. Bob went under the guise of anonymity to purchase the building conducting considerable renovations to the office for increased staff. Needless to say, Bob felt he had won the battle, and Chester was still alive to witness the spectacle.

By the mid 70’s, Gulf Canada located in Mississauga, Ontario was undergoing massive renovations at their facility and needed a blender to manufacture their lubricants under their name ~ Contract Blending ~ where the customer’s formula and packages are used, blending on behalf of the customer. Reminisce continues today from Albert Boyle, Forsythe’s VP, about that period where tankers of baseoil per day were offloaded at the front of the building, blended, and shipped out the back running 24/7. At that time our tank farm was built to enable the increased volumes and we continue to Contract Blend for now Petro Canada/Suncor today. That business put Forsythe on the map as a significant player in the lubricant marketplace as Contract Blender in Southwestern Ontario for major oil companies.

In the early 80’s, Forsythe established a new division and became a distributor of phosphate ester fluids for the power generation company and maintained the full industrial line of Forsythe lubricants and Contract Blending for major oil companies. During this time Bob’s daughter Dee Forsythe joined the family business in the administration and HR departments. Dee learned to be back up for the order desk and gained an understanding of the overall business until 1986 when she took time off to raise her two sons Smitty and Greg.

In 1989 Dee had an opportunity to purchase a seasonal business called PDQ Bulk Sealer that distributed driveway sealant, located at the back of the property of Forsythe Lubrication. Asphalt sealer was sold in bulk to businesses that sell door to door sealing driveways. It was a small business and easy to manage given there were a handful of products to maintain in inventory. Dee’s sons spent many days during the summers biking in the back lot of Forsythe and learning the basics of the business. Oftentimes driving around town, we would see potential customers and wave them down to give them a business card to grow the business which was effective. There was not the convenience of the internet at that time, and many of these customers did not advertise phone numbers. The business continued to grow and it was determined that asphalt sealer could be used on the foundations of buildings. Coal tar, a water based emulsion, was becoming popular and we added that product in bulk to inventory.

Later in the 90’s, Bob wanted to semi-retire and leave day to day running of operations to someone else. Several attempts were made parachuting a new hire in to fill the role, but without success. It was decided at that time that Dee would return to Forsythe in that capacity. First responsibilities included assisting Albert Boyle attain ISO 9001 certification that was necessary to continue business with large corporations. That was achieved in 1997.

In 1966 Bobby was made aware that Ontario Lubricating had gone into bankruptcy and the property at 120 Chatham Street was up for sale. Discussion with Gordon ensued who refused to sell it to Bob given their bitter history. Bob went under the guise of anonymity to purchase the building conducting considerable renovations to the office for increased staff. Needless to say, Bob felt he had won the battle, and Chester was still alive to witness the spectacle.

By the mid 70’s, Gulf Canada located in Mississauga, Ontario was undergoing massive renovations at their facility and needed a blender to manufacture their lubricants under their name ~ Contract Blending ~ where the customer’s formula and packages are used, blending on behalf of the customer. Reminisce continues today from Albert Boyle, Forsythe’s VP, about that period where tankers of baseoil per day were offloaded at the front of the building, blended, and shipped out the back running 24/7. At that time our tank farm was built to enable the increased volumes and we continue to Contract Blend for now Petro Canada/Suncor today. That business put Forsythe on the map as a significant player in the lubricant marketplace as Contract Blender in Southwestern Ontario for major oil companies.

In the early 80’s, Forsythe established a new division and became a distributor of phosphate ester fluids for the power generation company and maintained the full industrial line of Forsythe lubricants and Contract Blending for major oil companies. During this time Bob’s daughter Dee Forsythe joined the family business in the administration and HR departments. Dee learned to be back up for the order desk and gained an understanding of the overall business until 1986 when she took time off to raise her two sons Smitty and Greg.

In 1989 Dee had an opportunity to purchase a seasonal business called PDQ Bulk Sealer that distributed driveway sealant, located at the back of the property of Forsythe Lubrication. Asphalt sealer was sold in bulk to businesses that sell door to door sealing driveways. It was a small business and easy to manage given there were a handful of products to maintain in inventory. Dee’s sons spent many days during the summers biking in the back lot of Forsythe and learning the basics of the business. Oftentimes driving around town, we would see potential customers and wave them down to give them a business card to grow the business which was effective. There was not the convenience of the internet at that time, and many of these customers did not advertise phone numbers. The business continued to grow and it was determined that asphalt sealer could be used on the foundations of buildings. Coal tar, a water based emulsion, was becoming popular and we added that product in bulk to inventory.

Later in the 90’s, Bob wanted to semi-retire and leave day to day running of operations to someone else. Several attempts were made parachuting a new hire in to fill the role, but without success. It was decided at that time that Dee would return to Forsythe in that capacity. First responsibilities included assisting Albert Boyle attain ISO 9001 certification that was necessary to continue business with large corporations. That was achieved in 1997.

The internet became a new method of attracting new business globally and the first international distributor was from Thailand who we continue to supply today. There was a need for increased Contract Blending, so Albert and Dee paired up to make a formidable team with Albert’s technical background and Dee’s sales skills.

Forsythe won a Japanese Contract Blending contract for automotive factory fill of Automatic Transmission Fluid, and Power Steering Fluid, that would be another new division for Forsythe. It was necessary to step up to ISO TS16949, the certification for factory fill, as well as bringing in base oils and raw materials from around the globe. Tight specifications and zero cross contamination was a requirement, and dedicated systems were created to enable this business, that continues today. The team at Forsythe became experts with 100% OTIF (On Time In Full) statistics.

Forsythe was gaining significant fame in the marketplace for five star service, producing results that achieved global supplier awards.

A German company became aware of Forsythe’s capabilities and began significant automotive Contract Blending business with them manufacturing Shock Absorber Fluids that were shipped across North America and Mexico.

In 2008 when the recession hit, Dee’s eldest son Smitty joined Forsythe after completing University. His goals were to learn the overall business and spend time in all departments, including accounting, lab, operations and computer. Experience running Bulk Sealer for two summers was the training ground for business management. Smitty was responsible for converting Forsythe’s computer to updated technology that was possible from understanding all aspects of the business. Today most of his time is spent in Operations, Inventory Management and Financial Analysis.

Due to the long recession and downturn of manufacturing in Ontario, in 2009 there was a need for horsepower in sales, and Greg, Dee’s second son was willing to join Forsythe to hone his genetic nature for sales that appear to be in the bloodline of the Forsythe clan. His goal was to learn the products, applications, the marketplace and grow relationships with key contacts in the global lubricant industry. Greg is responsible for overall business development and marketing, including an overhaul of the website, and all product data and marketing literature. Sales and profits have continued to grow steadily and history appears to be repeating itself. Sadly, Bob passed away on August 27th 2012 in his 79th year. He was thrilled to see the fruits of his lifelong labours continue to 5th generation.

In 2013, Canadian Government standards were revised and all MSDS were needed to be updated, Dee’s stepdaughter Lydia was asked to provide assistance on this significant project for a summer. Business had grown considerably by this time and there was a void that required filling in the Operations Department. Lydia agreed to join Forsythe full time using her skill set with extreme attention to detail, purchasing raw materials and logistics for delivery, conduct inventory cycle counts, ISO auditing, and overall understanding of manufacturing and products.

Less than 1% of family owned businesses survive 3rd generation management and we are proud that Forsythe has maintained the high standards, business philosophies and principles that have earned us the reputation for over one century of being Canada’s Top Lubricant Contract Blender and Manufacturer.